Submersible Stainless Steel Pump US/NS/DS SERIES

Vortex Impeller

Channel Impeller

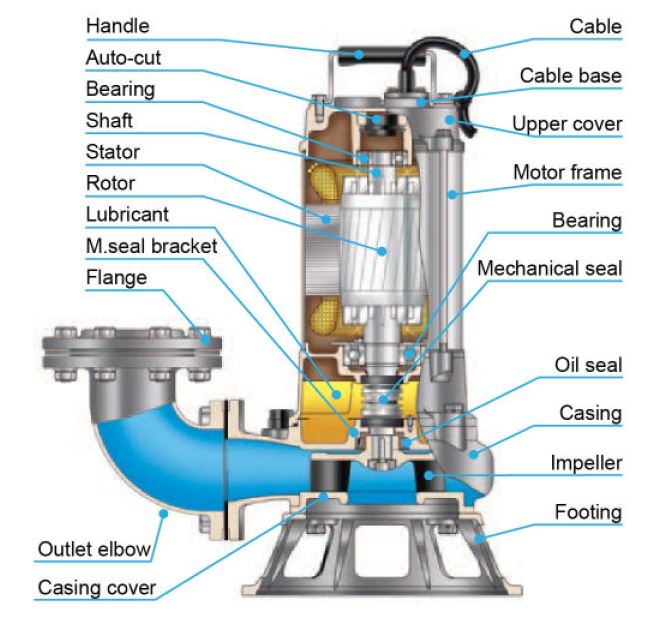

| ITEM | DESCRIPTION | |

|---|---|---|

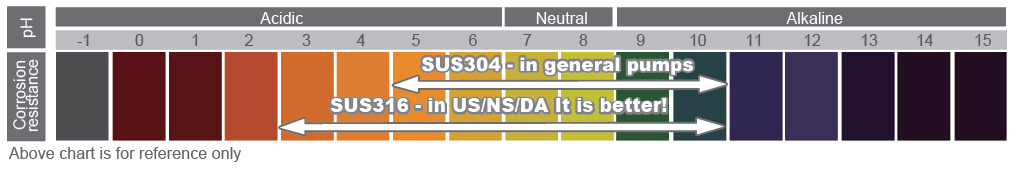

| Limits of Use | Liquid Temp. | 0-40°C (32-104 °F) |

| Applications | Corrosive/Food/Processing Liquid | |

| Frequency | 50Hz | |

| Type | Motor | 2P (3600rpm). Dry Motor |

| Insulation | Class F (0.4-3.7HP).Class H (5.5-11HP) | |

| Protection | IP68 | |

| Protector | Auto-Cut protector (built-in) up to 7.5 kW. MTS is from 11 kW. |

|

| Bearing | Ball type | |

| M.Seal | Double M.Seal | |

| Material | Impeller | Semi-open |

| Upper Cover | scs14 | |

| Motor Frame | SUS316 | |

| Shaft | SUS316 (0.4-7.5HP) SUS630 (11Kw) | |

| M.Seal | CA/CE &SiC/SiC | |

| Casing | Viton | |

| Impeller | SCS14 | |

| Casing Cover | scs14 | |

| Cable | VCTor H07RN-F or SJOW/SOW | |

| Optional | Pumps can be customized to fit specifications | |

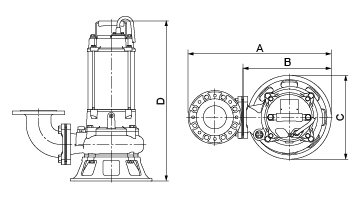

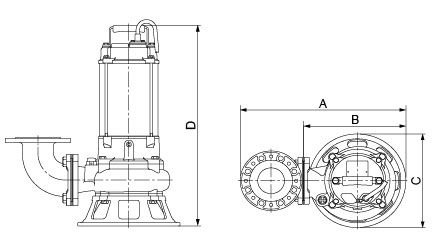

| MODEL | Output | Pole/Phase | Discharge Inch | Impeller | Start Method | Head | Standard | Solid Passage | Weight (kg) | Dimensions (mm.) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kW. | mm. | m. | m3/min | m3/h | mm. | A | B | C | D | |||||

| US2.4-2S | 0.4 | 2P/1 | 2″(50) | Vortex | Capacitor | 6 | 0.15 | 9 | 35 | 15 | 237 | 199 | 153 | 433 |

| US2.4-2 | 0.4 | 2P/3 | 2″(50) | Vortex | Direct | 6 | 0.15 | 9 | 35 | 14 | 237 | 199 | 153 | 433 |

| US2.8-2S | 0.75 | 2P/1 | 2″(50) | Vortex | Capacitor | 8 | 0.2 | 12 | 35 | 16 | 237 | 199 | 153 | 433 |

| US2.8-2 | 0.75 | 2P/3 | 2″(50) | Vortex | Direct | 8 | 0.2 | 12 | 35 | 15 | 237 | 199 | 153 | 433 |

| US1.5-3 | 1.5 | 2P/3 | 3″ (80) | Vortex | Direct | 8.5 | 0.4 | 24 | 50 | 26.5 | 402 | 260 | 202 | 517 |

| US2.2-3 | 2.2 | 2P/3 | 3″ (80) | Vortex | Direct | 13 | 0.4 | 24 | 50 | 29 | 402 | 260 | 202 | 517 |

| US3.7-3 | 3.7 | 2P/3 | 3″ (80) | Vortex | Direct | 17.5 | 0.5 | 30 | 50 | 40 | 476 | 286 | 222 | 561 |

| US25.5-3 | 5.5 | 2P/3 | 3″ (80) | Vortex | Direct | 21 | 0.6 | 36 | 50 | 61 | 499 | 309 | 258 | 657 |

| US27.5-3 | 7.5 | 2P/3 | 3″ (80) | Vortex | Direct | 26 | 0.6 | 36 | 50 | 67 | 499 | 309 | 258 | 657 |

| US211-3 | 11 | 2P/3 | 3″ (80) | Vortex | Star-Delta | 33 | 0.6 | 36 | 50 | 76 | 499 | 309 | 258 | 657 |

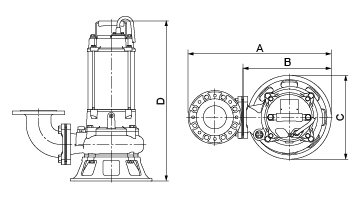

| MODEL | Output | Pole/Phase | Discharge Inch | Impeller | Start Method | Head | Standard | Solid Passage | Weight kg. | Dimensions (mm.) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kW. | mm. | m. | m3/min | m3/h | mm. | A | B | C | D | |||||

| NS21.5-3 | 1.5 | 2P/3 | 3″(80) | Channal | Direct | 8.5 | 0.6 | 36 | 35 | 28.5 | 417 | 275 | 260 | 521 |

| NS22.2-3 | 2.2 | 2P/3 | 3″(80) | Channal | Direct | 13 | 0.6 | 36 | 35 | 31.5 | 417 | 275 | 260 | 521 |

| NS23.7-3 | 3.7 | 2P/3 | 3″(80) | Channal | Direct | 20.5 | 0.6 | 36 | 32 | 43 | 495 | 305 | 290 | 568 |

| NS25.5-3 | 5.5 | 2P/3 | 3″(80) | Channal | Direct | 28 | 0.6 | 36 | 30 | 67 | 563 | 373 | 345 | 684 |

| NS25.5-4 | 5.5 | 2P/3 | 4″ (100) | Channal | Direct | 21.5 | 1 | 60 | 30 | 67 | 591 | 373 | 345 | 684 |

| NS27.5-3 | 7.5 | 2P/3 | 3″ (80) | Channal | Direct | 35.5 | 0.6 | 36 | 30 | 73 | 563 | 373 | 345 | 684 |

| NS27.5-4 | 7.5 | 2P/3 | 4″ (100) | Channal | Direct | 29 | 1 | 60 | 30 | 73 | 591 | 373 | 345 | 684 |

| NS211-3 | 11 | 2P/3 | 3″ (80) | Channal | Star-Delta | 46 | 0.6 | 36 | 30 | 82 | 563 | 373 | 345 | 724 |

| NS211-4 | 11 | 2P/3 | 4″ (100) | Channal | Star-Delta | 39.5 | 1 | 60 | 30 | 82 | 591 | 373 | 345 | 724 |

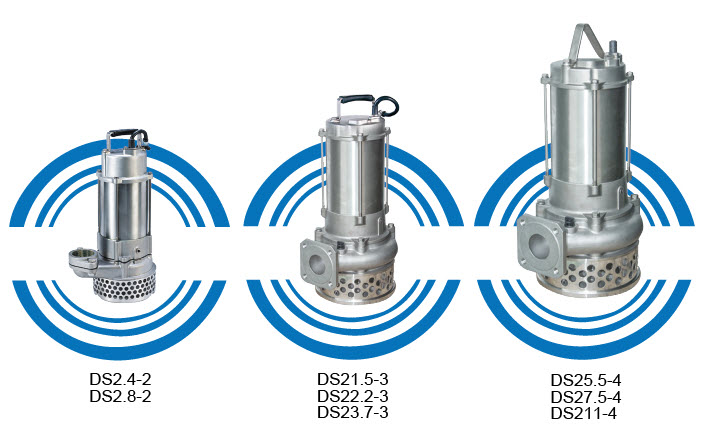

| MODEL | Output | Pole/Phase | Discharge Inch | Impeller | Start Method | Head | Standard | Solid Passage | Weight (kg) | Dimensions (mm.) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kW. | mm. | m. | m3/min | m3/h | mm. | A | B | C | D | |||||

| DS2.4-2S | 0.4 | 2P/1 | 2″(50) | Vortex | Capacitor | 7 | 0.12 | 7.2 | 10 | 14 | 244 | 206 | 172 | 437 |

| DS2.4-2 | 0.4 | 2P/3 | 2″(50) | Vortex | Direct | 7 | 0.12 | 7.2 | 10 | 14 | 244 | 206 | 172 | 437 |

| DS2.8-2S | 0.75 | 2P/1 | 2″(50) | Vortex | Capacitor | 10 | 0.17 | 10.2 | 10 | 16 | 244 | 206 | 172 | 437 |

| DS2.8-2 | 0.75 | 2P/3 | 2″(50) | Vortex | Direct | 10 | 0.17 | 10.2 | 10 | 15 | 244 | 206 | 172 | 437 |

| DS21.5-3 | 1.5 | 2P/3 | 3″ (80) | Channel | Direct | 8.5 | 0.6 | 36 | 20 | 29.5 | 390 | 248 | 212 | 520 |

| DS22.2-3 | 2.2 | 2P/3 | 3″ (80) | Channel | Direct | 13 | 0.6 | 36 | 20 | 32.5 | 390 | 248 | 212 | 520 |

| DS23.7-3 | 3.7 | 2P/3 | 3″ (80) | Channel | Direct | 20.5 | 0.6 | 36 | 20 | 44.5 | 465 | 275 | 239 | 568 |

| DS25.5-3 | 5.5 | 2P/3 | 3″ (80) | Channel | Direct | 28 | 0.6 | 36 | 20 | 67 | 528 | 338 | 286 | 684 |

| DS25.5-4 | 5.5 | 2P/3 | 4″ (100) | Channel | Direct | 21.5 | 1 | 60 | 20 | 67 | 556 | 338 | 286 | 684 |

| DS27.5-3 | 7.5 | 2P/3 | 3″ (80) | Channel | Direct | 35.5 | 0.6 | 36 | 20 | 73 | 528 | 338 | 286 | 684 |

| DS27.5-4 | 7.5 | 2P/3 | 4″ (100) | Channel | Direct | 29 | 1 | 60 | 20 | 73 | 556 | 338 | 286 | 684 |

| DS211-3 | 11 | 2P/3 | 3″ (80) | Channel | Star-Delta | 46 | 0.6 | 36 | 20 | 82 | 528 | 338 | 286 | 724 |

| DS211-4 | 11 | 2P/3 | 4″ (100) | Channel | Star-Delta | 39.5 | 1 | 60 | 20 | 82 | 556 | 338 | 286 | 724 |

© 2022 KIRA PUMP MANUFACTURING CO., LTD.