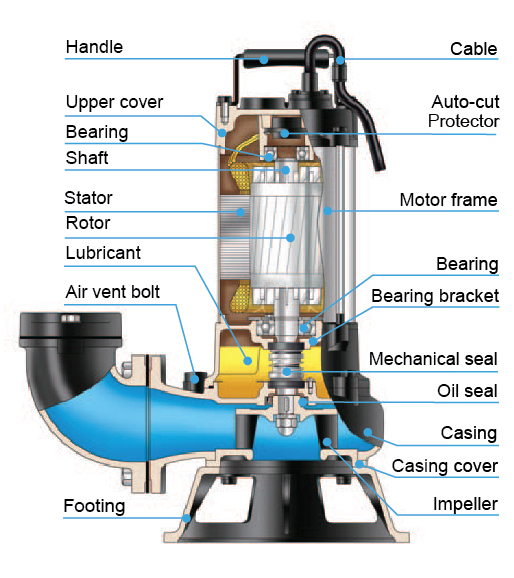

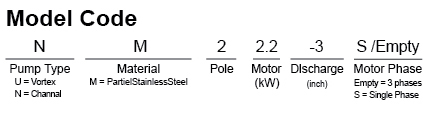

Submersible Sewage Drainage Pump UM/NM SERIES

Superior abrasion resistant mechanical seal

manafactured with silicon carbide to ensure

the best seal effect.

All stator coils need to be treated with insulating

varnish procedure to achieving the best insulation, efficiency and durability.

Automatic On/Off motor protector to prevent motor burn out due to high temperature and excess amperage draw.

An epoxy resin seal cable base prevents moisture

from entering the motor through the core wires.

Excellent to use with waste materials to prevent from clogging.

Produces a vortex (whirpool effect) allowing long fibrous materials and other solid waste to pass through, without contact with the impeller.

| ITEM | DESCRIPTION | |

|---|---|---|

| Limits of Use | Liquid Temp. | 0 ~ 40°C (32 ~ 104° F ) |

| Applications | General Wasterwater Sewage water and lndustrial waster |

|

| Type | Frequency | 50 Hz |

| Motor | 2P (3000rpm) Dry Motor |

|

| Insulation | Class F (0.4-3.7 kW) Class H (11 kW) |

|

| Protection | IP68 | |

| Protector | Auto-cut Protector (built-in) |

|

| Bearing | Ball Type | |

| M.seal | Double M.seals | |

| Impeller | Vortex / Channel | |

| Material | Upper Cover | FC200 |

| Motor Frame | SUS304 | |

| Shaft | SUS410 (0.4 ~ 0.75 kW) SUS403 (1.5 ~ 3.7 kW) |

|

| M.seal | Upper : Carbon/Ceramic Lower : Silicon/Silicon |

|

| Casing | FC200 | |

| Impeller | FC200 | |

| Casing | VCT or H07RN-F Or SJOW/SOW | |

| Optional | Pumps can be customized to fit specifications |

|

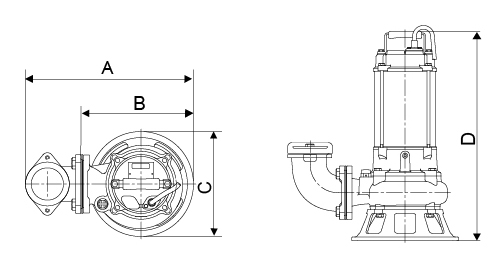

| Model | Output | Pole / Phase | Discharge | Impeller | Start | Head | Flow | Solid Passage | Weight | Dimensions (mm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kW | inch (mm) | Method | m | m3/ min | m3/h | mm | kg | A | B | C | D | |||

| UM2.4-2S | 0.4 | 2P/1 | 2" (50) | Vortox | Capacitor | 6 | 0.15 | 9 | 35 | 16 | 237 | 0 | 154 | 425 |

| UM2.4-2 | 0.4 | 2P/3 | 2" (50) | Vortox | Direct | 6 | 0.15 | 9 | 35 | 15 | 237 | 0 | 154 | 425 |

| UM2.8-2S | 0.75 | 2P/1 | 2" (50) | Vortox | Capacitor | 8 | 0.2 | 12 | 35 | 17 | 237 | 0 | 154 | 425 |

| UM2.8-2 | 0.75 | 2P/3 | 2" (50) | Vortox | Direct | 8 | 0.2 | 12 | 35 | 16 | 237 | 0 | 154 | 425 |

| UM2.8-3S | 0.75 | 2P/1 | 3" (80) | Vortox | Capacitor | 6.5 | 0.3 | 18 | 30 | 18 | 278 | 0 | 154 | 456 |

| UM2.8-3 | 0.75 | 2P/3 | 3" (80) | Vortox | Direct | 6.5 | 0.3 | 18 | 30 | 17 | 278 | 0 | 173 | 456 |

| UM21.5-2S | 1.5 | 2P/1 | 2" (50) | Vortox | Capacitor | 14 | 0.2 | 12 | 35 | 30 | 288 | 0 | 173 | 546 |

| UM21.5-2 | 1.5 | 2P/3 | 2" (50) | Vortox | Direct | 14 | 0.2 | 12 | 35 | 25 | 288 | 0 | 202 | 477 |

| UM21.5-3S | 1.5 | 2P/1 | 3" (80) | Vortox | Capacitor | 8.5 | 0.4 | 24 | 50 | 32 | 402 | 260 | 202 | 588 |

| UM21.5-3 | 1.5 | 2P/3 | 3" (80) | Vortox | Direct | 8.5 | 0.4 | 24 | 50 | 28 | 402 | 260 | 202 | 519 |

| UM22.2-3S | 2.2 | 2P/1 | 3" (80) | Vortox | Capacitor | 12.5 | 0.4 | 24 | 50 | 35 | 402 | 260 | 202 | 600 |

| UM22.2-3 | 2.2 | 2P/3 | 3" (80) | Vortox | Direct | 12.5 | 0.4 | 24 | 50 | 30 | 402 | 260 | 202 | 519 |

| UM23.7-3 | 11 | 2P/3 | 3" (80) | Vortox | Direct | 16.5 | 0.5 | 30 | 50 | 33 | 403 | 260 | 202 | 539 |

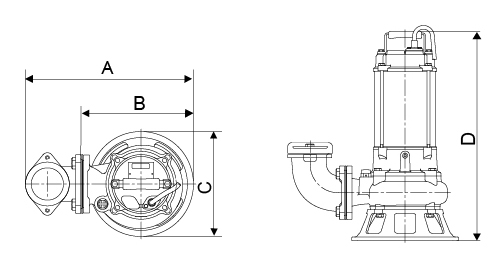

| Model | Output | Pole / Phase | Discharge | Impeller | Start | Head | Flow | Solid Passage | Weight | Dimensions (mm) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| kW | inch (mm) | Method | m | m3/ min | m3/h | mm | kg | A | B | C | D | |||

| NM2.4-2S | 0.4 | 2P/1 | 2" (50) | Channel | Capacitor | 5.5 | 0.2 | 12 | 22 | 16 | 276 | 238 | 235 | 459 |

| NM2.4-2 | 0.4 | 2P/3 | 2" (50) | Channel | Direct | 5.5 | 0.2 | 12 | 22 | 15 | 276 | 238 | 235 | 459 |

| NM2.8-2S | 0.75 | 2P/1 | 2" (50) | Channel | Capacitor | 9 | 0.2 | 12 | 26 | 18 | 276 | 0 | 235 | 459 |

| NM2.8-2 | 0.75 | 2P/3 | 2" (50) | Channel | Direct | 9 | 0.2 | 12 | 26 | 17 | 276 | 0 | 235 | 459 |

| NM21.5-3S | 1.5 | 2P/1 | 3" (80) | Channel | Capacitor | 8.5 | 0.6 | 36 | 35 | 34 | 417 | 275 | 260 | 590 |

| NM21.5-3 | 1.5 | 2P/3 | 3" (80) | Channel | Direct | 8.5 | 0.6 | 36 | 35 | 30 | 417 | 275 | 260 | 521 |

| NM22.2-3S | 2.2 | 2P/1 | 3" (80) | Channel | Capacitor | 12.5 | 0.6 | 36 | 35 | 37 | 417 | 275 | 260 | 602 |

| NM22.2-3 | 2.2 | 2P/3 | 3" (80) | Channel | Direct | 12.5 | 0.6 | 36 | 35 | 32 | 417 | 275 | 260 | 521 |

| NM23.7-3 | 3.7 | 2P/3 | 3" (80) | Channel | Direct | 19 | 0.6 | 36 | 35 | 35 | 468 | 275 | 260 | 541 |

ELBOW/GUIDE RAIL SYSTEMS

Pump can be installed with 90° Elbow with Flang or GRS quick coupling system, for safe installation, removal, replacement and maintenance purpose.

© 2022 KIRA PUMP MANUFACTURING CO., LTD.